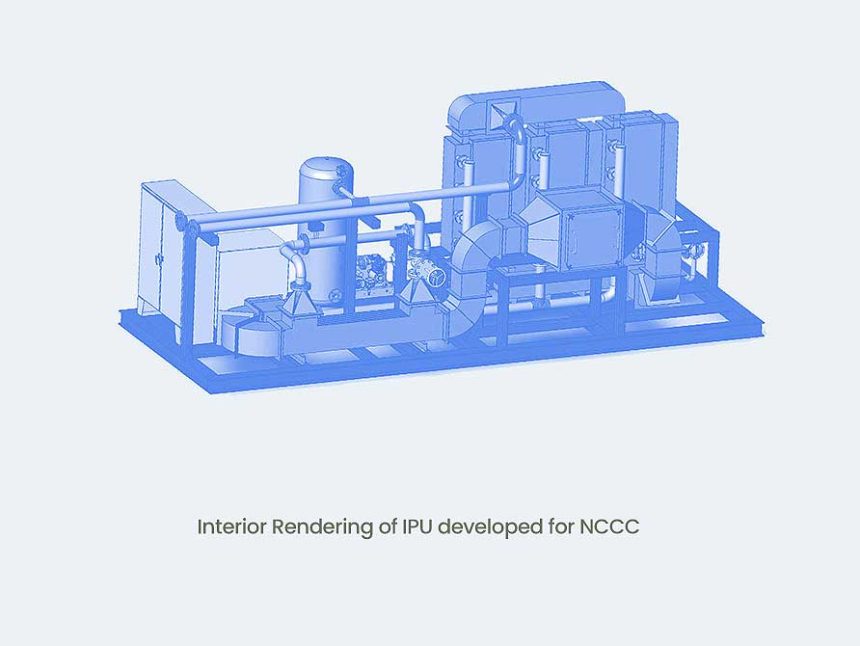

The U.S. refinery industry has spent billions of dollars since 1990 to comply with federal environmental regulations. Increased scrutiny to reduce emissions associated with NOx, NH3 slip, and SO2 oxidation has significantly added to the costs of manufacturing refined products. Applying effective SCR Catalyst best practices can increase catalyst life, reliability, and performance while decreasing total emissions compliance costs.

Richard Weiland, Project Engineer at Cormetech, will present an informative webinar that provides an overview of current SCR catalyst technologies and actionable best practices for refinery/petrochemical SCR applications, covering the following topics:

- Basic SCR Catalyst design principles and performance drivers

- Refinery/Petrochemical application emissions challenges

- SCR Catalyst lifecycle and asset optimization strategies

- SCR best practices for scheduled and unscheduled unit outages

In this webinar you will also learn:

- Preventive maintenance measures to improve SCR performance and reliability

- Answers to industry and application specific questions from current SCR users

- SCR technology solutions to address emissions constraints and challenges

- The benefits of data monitoring and catalyst sampling

Richard Weiland | Project Engineer

Richard Weiland | Project Engineer

Richard specializes in SCR system design for a wide-range of applications in the refinery / petrochemical industry as well as natural gas HRSGs and coal-fired power plants. He also has an experience base in field service unit troubleshooting, maintenance, and plant technical support. In addition, he has managed catalyst testing services adhering to individual plant operation and performance requirements for refinery / petrochemical, gas and coal fired facilities across the country. His background includes degrees in both chemical engineering and business administration.