At the Heartof Clean Air

At the Heart of Clean Air

Catalysts

Carbon Capture

CORMETECH is a global leader in the design, manufacture, and full lifecycle management of technologies that clean the air of pollutants and carbon dioxide (CO₂) linked to climate change. We breathe innovation so the world can breathe easy.

o2 / OUR foundation

World Class Catalysts

o2 / OUR foundation

World Class Catalysts

o2 / OUR foundation

World Class Catalysts

We innovate with eyes on the skies.

With a universal consensus on the need to fight climate change, CORMETECH is the company at the forefront to provide common-sense solutions. No industry player is better positioned than CORMETECH to meet this challenge — now and in the years to come.

Designing for Change

o3 / OUR future

Carbon Capture Here We Come

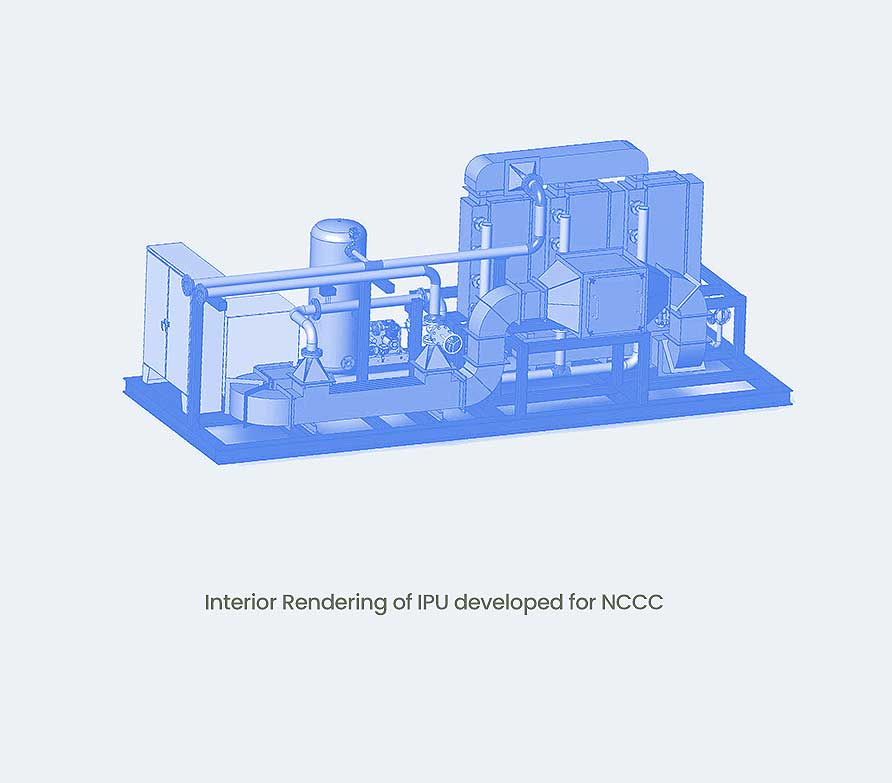

At CORMETECH, progress is in the air: with the use of our superior technology, we’re creating the building blocks for the carbon capture initiatives required to help avert the climate crisis, providing efficient and cost-effective Direct Air Capture and Point Source Capture solutions.

o3 / OUR future

Carbon CaptureHere We Come

DirectAirCapture

- Carbon Capture Hubs

- Commercial CO₂ Utilization

PointSource Capture

- NG Power Plants

- Industrial Applications

Direct Air Capture

- Carbon Capture Hubs

- Commercial CO2 Utilization

Point Source Capture

- NG Power Plants

- Industrial Applications

OUR differentiators

Proven Technology.Superior Services.

Circular Lifecycle Management

Cost Effective

02 / 04

DESIGNED FOR EFFICIENCY

Increased Capture Capability

03 / 04

EFFECTIVE FORM + FUNCTION

Adaptable and Scaleable

04 / 04

VERSATILE TO YOUR NEEDS

o4 / OUR differentiators

Proven Technology. Superior Services.

CORMETECH provides circular lifecycle management, from the installation of the adsorber, to monitoring and inspection, all the way to replacement thanks to CORMETECH’s unique regenerable and recyclable adsorbers, lowering carbon footprints and supply chain risks.

DESIGNED FOR EFFICIENCY

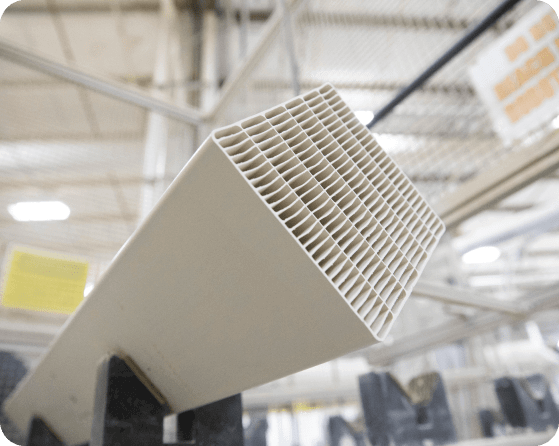

CORMETECH designs and manufactures industry-leading honeycomb substrates, renowned for maximizing gas contact with lower pressure drop, greatly reducing electric demand and cost.

EFFECTIVE FORM + FUNCTION

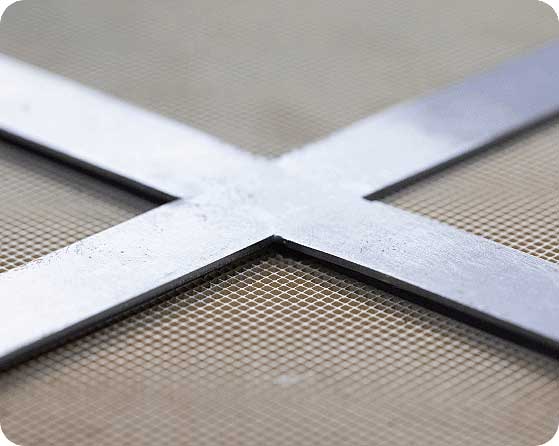

Functional walls embedded within the honeycomb structure improve the thermal efficiency of the adsorb cycle, all while reducing the parasitic energy load and minimizing inert mass, leading to a much higher capture capacity.

VERSATILE TO YOUR NEEDS

CORMETECH products are customized for each sorbent and substrate pairing — a crucial part of improving performance — eliminating the need for an additional supply chain vendor.

EXPLORE OUR SERVICES

EXPLORE OUR SERVICES  REGENERATION + RECYCLING

REGENERATION + RECYCLING  EXPLORE OUR SERVICES

EXPLORE OUR SERVICES  REGENERATION + RECYCLING

REGENERATION + RECYCLING

EXPLORE OUR SERVICES

EXPLORE OUR SERVICES  REGENERATION + RECYCLING

REGENERATION + RECYCLING EXPLORE OUR SERVICES

EXPLORE OUR SERVICES  REGENERATION + RECYCLING

REGENERATION + RECYCLING

o5 / OUR latest

News & Views

o6 / OUR IMPACT

We’re A Breath

of

Fresh Air

Thirty years of pioneering public health and environmental solutions.

SINCE 1995

U.S. NOx EMISSIONS REDUCTIONS

SINCE 1995

Services

Get In Touch

1 704 827 8933

11707 Steele Creek Road

Charlotte, NC 28273

info@cormetech.com